High quality engineered solutions

Ideally suited for high care and clean room environments, Packline’s stainless steel ‘Compac’ range of roll and reel lifting and handling equipment is the market leader both in the UK and worldwide.

Reel and roll handling refers to safely lifting, transporting, rotating, positioning, loading (or unloading) of cylindrical materials—film, foil, paper, textiles, etc. In industrial, food, pharmaceutical or packaging operations, reels and rolls can be heavy, awkward, and risky to move manually. Proper handling systems improve safety, reduce damage, speed up workflows, and help meet hygiene or regulatory requirements.

Packline is a UK-based designer and manufacturer offering a range of reel or roll lifting and handling equipment engineered to address these challenges.

Reel & roll handling, when done properly, improves workplace safety, reduces waste/damage, speeds up operations, and ensures compliance with hygiene or safety standards. Packline offers a wide spectrum of solutions—from simple dollies, to fully motorised stainless steel reel lifters with rotation, grip, safety features and bespoke attachments. The key is matching the right features to your environment, load types, frequency of use—and investing in quality, safety and ergonomics.

Packline’s reel & roll handling equipment falls into a few categories, each suited to different situations: stainless steel vs painted mild steel; manual, semi-powered or fully motorised; and various attachments to suit core gripping, outer diameter gripping, vertical or horizontal orientations.

Here are some of the main varieties and special features:

When selecting equipment like Packline’s, several factors should guide you:

Safe, Hygienic, and Custom-Built Reel Handling Solutions

Engineered in stainless steel for cleanroom and industrial environments – built to lift smarter, safer, and more efficiently.

Ready to Improve Your Reel Handling Process?

Contact Packline today to discuss your specific requirements and discover how our custom-built stainless steel reel lifting equipment can transform your operations.

Ideally suited for clean room environments, the Stainless Steel Compac range of Reel and Roll Handling Equipment from Packline, is popular both here and worldwide, proving to be a winner with customers operating in the following industries:-

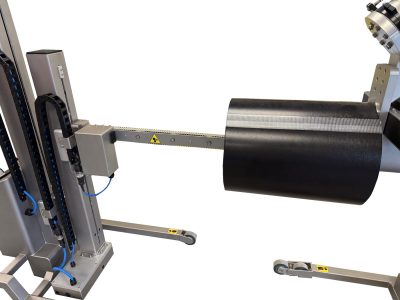

The purpose-designed compact framework, positioning of handlebars and addition of an optional joystick control and remote control device provide improved manoeuvrability and ease of use for the operator. The incredibly small footprint makes the Compac Lifting Machine highly manoeuvrable and a natural choice for today’s narrow production lines and demanding lifting requirements.

Taking account of the latest UK health and safety standards and EU directives, additional safety features have been incorporated to further protect operating personnel and satisfy the increasing demands of insurance companies.

Safety Features include:-

Designed to lift, transport and position loads, the Compac has been the name associated with top quality, reliable, stainless steel lifters for many years; and the latest model, the Mk5.1 has been developed following extensive market research into the lifting and handling needs of today’s modern production environment.

The Compac is flexible in design, ergonomic, operator friendly, easy to use, and, with its range of features and functionality it meets the needs of today’s lifting requirements.

Primarily manufactured from stainless steel, the Mk5.1 Compac is ideal for industries where hygiene and resistance to chemicals is of paramount importance including Food and Dairy, Medical, Chemical, Pharmaceutical and Cosmetics.

With a small footprint and easy operation, the Compac can be used in the confined work spaces and narrow production lines found in many of today’s modern manufacturing environments.

Available in two standard models with maximum lifting capacities of 150kg, and 300kg, along with a variety of frame configurations and a comprehensive range of interchangeable attachments, the Compac is an ideal choice for most lifting applications. A full design and manufacture bespoke service is also available.

Engineered and tested to our own exacting quality standards, the Compac has been designed to provide a low maintenance, reliable and robust machine that has been built to last.

The Compac Lifting Machine is designed and manufactured in the UK. Considering operator safety at all times, the Compac has been designed to meet the latest international Health & Safety directives, CE and UKCA approved with supporting risk assessment, technical files and documentation.